Please note: Stephenson’s Rocket is no longer on display at the Science and Industry Museum. To find out what exhibitions and activities are open today, visit our What’s On section.

This locomotive is one of the best known in the history of railways. It was a prototype, one of a series designed by Robert Stephenson (1803–1859) between 1828 and 1830. During this time he introduced several innovations which served to improve the design, performance and efficiency of steam-hauled transport. The locomotives were all built at the Newcastle upon Tyne factory of Robert Stephenson and Co.

Rocket was not designed by George Stephenson, as is so often thought, because he was fully engaged in the building of the Liverpool and Manchester Railway at that time. However, as innovations were tried out by his son, Robert, in Newcastle, he was kept fully informed of the progress. Each prototype was built to the order of coal mining companies anxious to try out the new technology as it was made.

When ‘Travelling Engine No.19’, which later became known as Rocket, was being designed, the Liverpool and Manchester Railway announced that it was to hold competitive trials at Rainhill, near Liverpool, to determine the best locomotive design suitable for its operations when they started the following year. Every effort therefore went into making the new engine faster and more efficient than those that had preceded it.

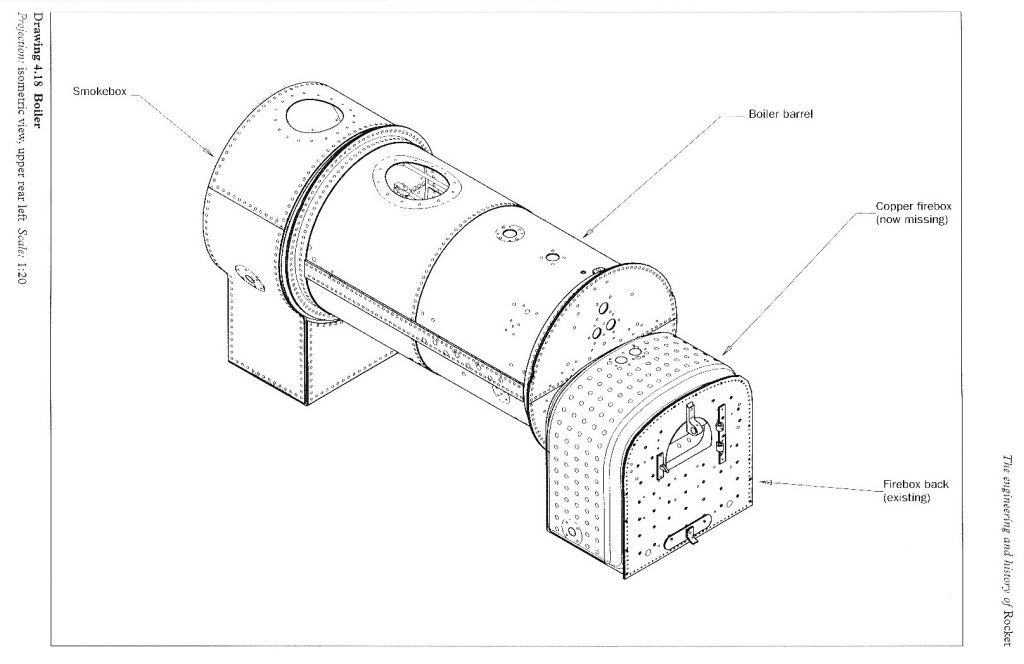

No.19 was built as a light machine with a radically new type of boiler. Instead of having a single flue inside the barrel, through which the hot gases from the fire passed, Stephenson innovated with having 25 smaller tubes, three inches in diameter, passing through the barrel fitted within tube-plates, one at each end of the barrel. The surface area of the tubes was considerably greater than that of a single flue, and thus allowed more heat to pass from the hot gases to the water. The increased heating area allowed much more steam to be created allowing sustained operation at higher speeds, and for longer periods than hitherto attained.

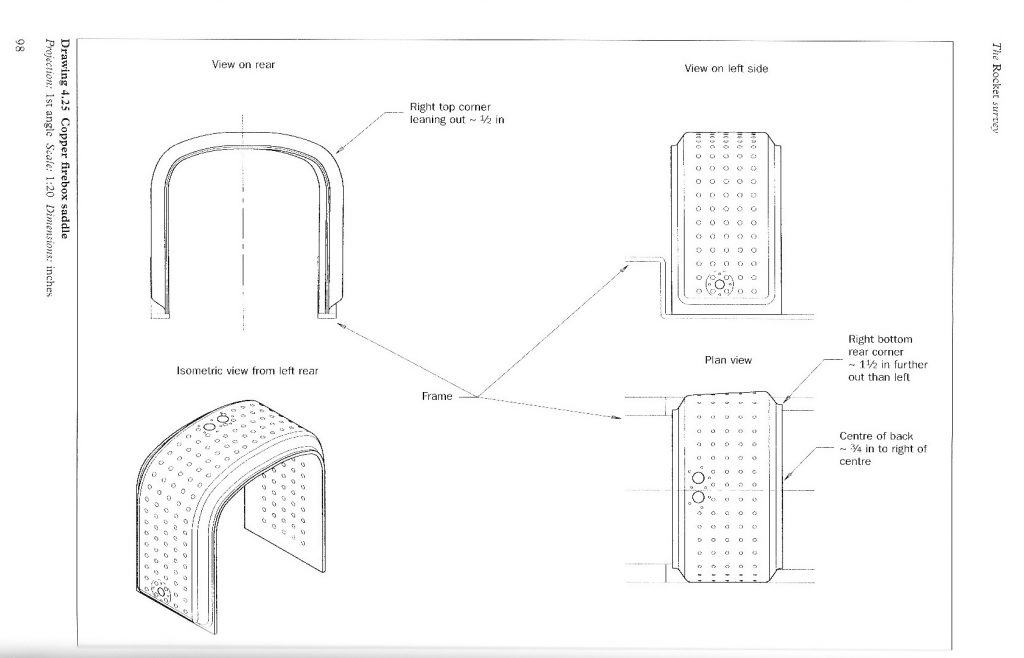

The problem that Stephenson had to resolve is that, if the boiler was fitted with smaller tubes, where was he to put the fire? A separate ‘fire-box’ was required, the heat from which could be directed readily through the boiler tubes. The innovation was to make the box with a double thickness of plates, formed to provide a space between for the water. Its shape was in the form of a saddle, forming the sides and crown around the fire-grate. The box containing the fire-grate was fitted to the back tube-plate of the barrel, allowing the hot gases to pass directly through the tubes.

To complete the box, a rear back-plate was fitted, through which a door allowed the crew to feed coke to the grate. To provide excellent conductivity from the hot gases to the water, the sides and crown of the fire-box were made of copper plate. The steam generated within the firebox passed to the upper part of the boiler barrel through two short steam-pipes above the crown. The locomotive was required to burn coke rather than coal to meet the strict requirements of the railway’s Act of Parliament which required it to ‘consume its own smoke’ in an endeavour to limit fire damage to the cotton bales and other vulnerable materials to be transported by the railway, as well as the risk to passenger’s clothes.

The steam cylinders were placed on both sides at the rear of the boiler, fed by short steam pipes from the barrel controlled by an intermediate regulator valve controlled by the driver. The diagonal driving motion directed the piston action down to the driving wheel crank pins. The steam was directed to the two ends of the cylinders by valves driven by, and linked from, eccentric drivers rotating about the driving axles. The locomotive was reversed by an axial movement of the eccentrics between forward and reverse ‘dogs’ clamped to the axle.

No.19 was tested, shortly after completion, on the Killingworth wagonway near to Newcastle. Adjustments were made back at the Stephenson factory, and a graduated mercurial gauge was fitted to its chimney allowing the observer to measure the rarefaction of the vacuum in the smokebox when testing out alternative forms of blast-pipe. Following the modifications, the locomotive was partly dismantled and forwarded by horse-drawn transport across the Pennines to Port Carlisle for shipment to Liverpool down the west coast of the country.

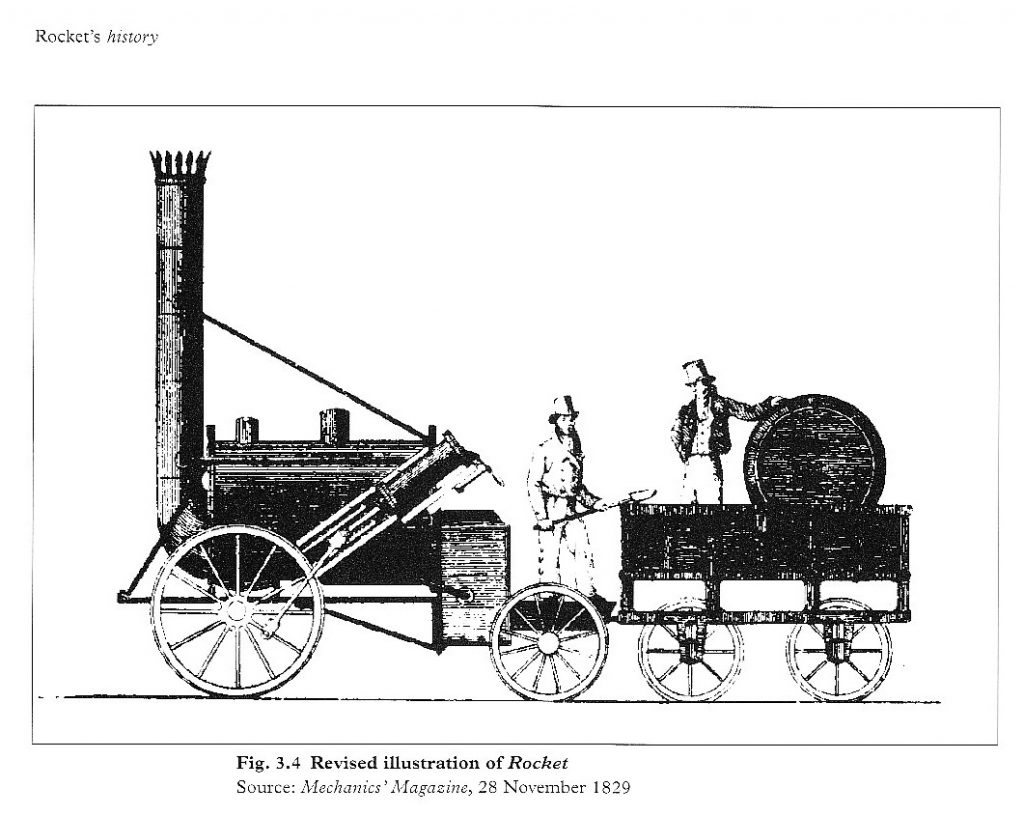

On arrival at Liverpool the locomotive was re-erected and tested prior to the trials at Rainhill. During this time sparks were noted to emit from the chimney at speed, particularly at night, probably giving rise to its similarity to Sir William Congreve’s military rockets, and the name Rocket was born. The locomotive went on to achieve success at the Rainhill Trials and, hence, immortality in the annals of history. Locomotive design progress continued apace during 1830, partly arising from what had been learned from Rocket’s performance, and in September that year the first of the Planet class was completed, that became the regular class used on the Liverpool and Manchester and later rail lines. Such was the progress that had been made that, by the opening of the line, Rocket was ‘old’ technology and it was relegated to secondary duties, requiring it to be re-built on several occasions.

The remains of Rocket we see today on display at the Science and Industry Museum look different from the locomotive seen at the Rainhill Trials, partly because of the dull patina of its finish compared to its bright yellow paintwork when it was first made. A larger smokebox has been fitted to its front end, and its cylinders have been lowered from the upper part of the boiler down to a near horizontal position. Remarkably, the wrought iron frame and original boiler barrel remain, but the firebox ‘saddle’ is missing. The driving wheels are early replacements, whilst the trailing wheels are latter-day replacements.

Readers seeking to learn more detail about Rocket’s career, and to understand more about its component history, form and function may like to consult the following publication:

The Engineering and History of Rocket by Michael R. Bailey and John P. Glithero, published by the Science Museum and National Railway Museum in 2000.

Very informative. Saw Rocket at the National Railway Museum in January so it is of interest to know something of its history. I was particularly impressed by both the design and the quality of construction of the eccentric valve drive for its early date.

I’m doing a little project comparing various locomotives of past and present, and I wondered if you could tell me the length of the Rocket, and also it’s tractive effort?

Many thanks,